August - CAD and Manufacturing Review

Computer-aided design is a perishable skill, so I dedicated time to relearning the basics of SolidWorks.

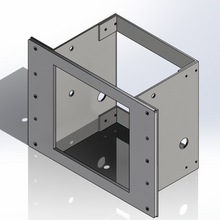

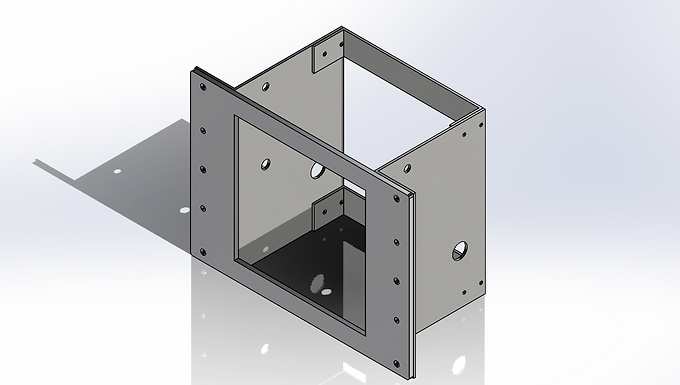

Computer-aided design is a perishable skill, so I dedicated time to relearning the basics of SolidWorks. I focused on two sub-assemblies of The One Calorie Workout's Counter, a senior exhibit. The first sub-assembly, the Frame, consists of three parts: the Front Cover Plate, Side Plate, and Rear Strap. These parts primarily required tools such as Boss Extrude, Extruded Cut, and Hole Wizard, allowing me to complete them confidently. To assemble the Frame (Figure 1), I had to recall how to use concentric and coincident mates. One challenge I encountered during this process was modifying the Side Plate. I had to revisit the part and add holes in a second iteration, but I was initially unsure of the correct placement. After collaborating with my mentor, Dr. Gibson, I determined the placement by referencing the Front Cover Plate's dimensions.

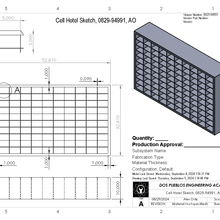

Along with reviewing CAD, I helped train others in CAD and even collaborated with Gibson to design a model of a new cellphone hotel for the DPEA. I completed a rough design of the hotel as a part in SolidWorks, but this was a more difficult process than I had expected. To minimize the use of Smart Dimensions, I mainly relied on line relationships to define distances. Construction lines proved to be a useful tool here. I had to redo parts of the work because I discovered this method late, but I still successfully created an accurate depiction of the original concept. Once the part was completed, I created a drawing (Figure 2) with appropriate dimensions and model views to illustrate the final product.

DELTAS

Translating knowledge to different contexts: I was only placed in lathe training for a day, but I made productive use of my time. Learning how to operate a Hardinge lathe in the senior shop (Figure 3) required me to apply machine shop knowledge from prior years. When I went to identify parts of a lathe, I was able to recall the functions of the chuck, spindle, collet, and other components. This allowed me to analyze nearby components and decipher their functions as well. Facing a part on the Hardinge lathe felt intimidating at first; I was concerned about operating the machine properly. However, using the handwheels helped me orient myself and make an even cut.

Coaching: Being a CAD trainer allowed me to expand my coaching skills. Many students ran into issues that I had already worked through earlier that day, so this allowed me to sit down with them and guide them through the process. My goal wasn't to tell them what to do, but instead to give them the groundwork to approach the problem on their own if needed.